CAPABILITIES

COMPLETE INFRASTRUCTURE FOR THE METAL INDUSTRY

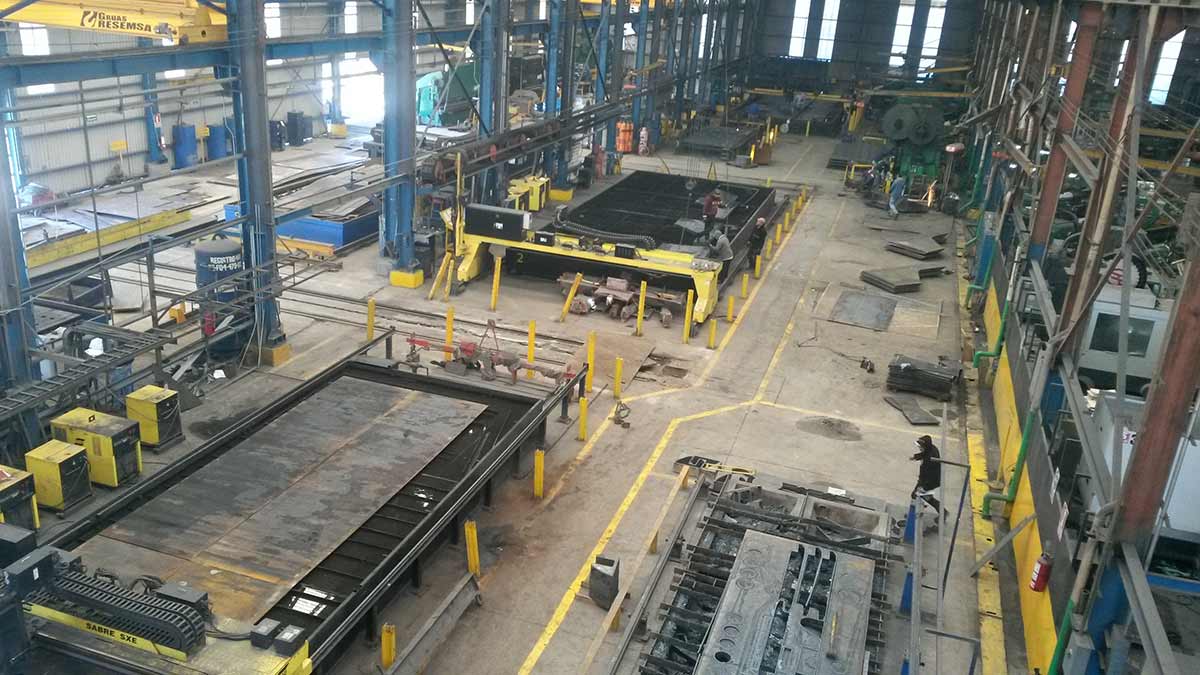

INFRASTRUCTURE

We have 4 plants with a total area of 76 acres (31 hectares) of which 184,540 square feet (17,144 square meters) under roof with overhead carriers.

PRODUCTS

Manufacture of larger Sub-Assemblies for Rail Cars.

Manufacture of trolley for transport of steel pot / steel industry.

PROCESSES

CUTTING

PRESS BRAKE

PUNCHING

MACHINING

WELDING

HEAT TREATMENT

PAINTING

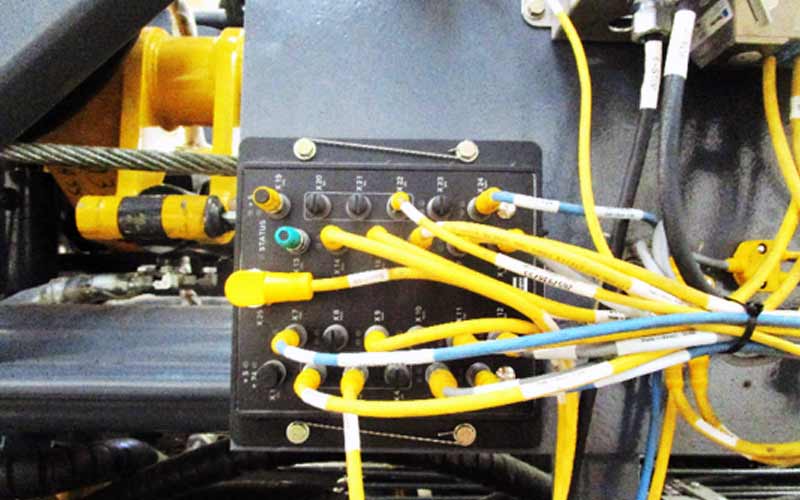

ASSEMBLY ELECTRICAL, METAL AND HIDRAULIC

PROCESS CONTROL

Process sheets and work instructions

WPS & PQR

Fixtures

Inspection records

Equipment calibration programs

Process auditors programs

KPI monitoring

Inspections throughout the process and final

Inspection under CMM laser equipment

PERSONNEL

More than 250 welders qualified under the following standards and specifications:

AWS D15.1

AWS D1.1

AAR M-1002

ASME section IX

Qualified personnel in operations:

CNC OPERATIONS

CONVENTIONAL OPERATIONS

Inspection personnel qualified in:

VISUAL INSPECTION

MAGNETIC PARTICLES

ULTRASOUND LEVEL II

CWI / CWE ASNT LEVEL III - SUBCONTRACTED

OPERATOR CMM

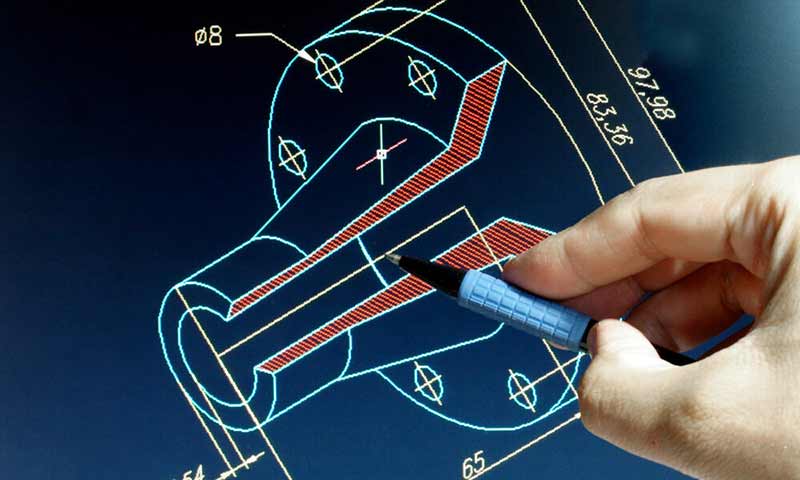

SOFTWARE

CAD: AutoCAD

ProNEST

MasterCAM

Solid Works

CAD: AutoCAD

Finite Element Analisys

ERP: Visual Manufacturing

TRAINING

We have professional training schools for our staff.